Namibia has an opportunity to anchor and grow its secondary sector by using locally produced direct reduced iron ore (DRI) as a hydrogen carrier for strategic reserves internationally.

A recent study by the Climate Neutrality Foundation shows that back-up power plants that produce electricity using hydrogen based on imported green iron can be a cost-effective supplement to power plants that work with green hydrogen.

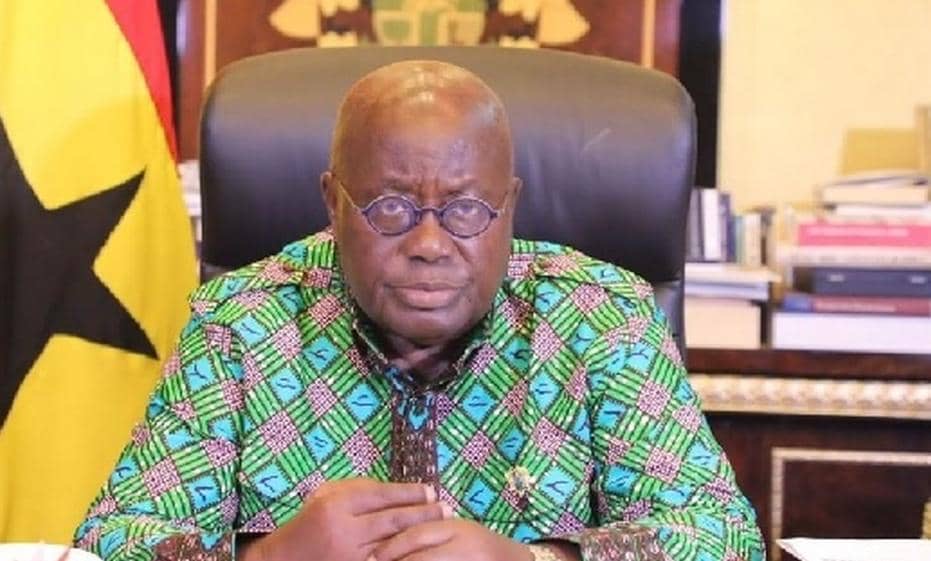

Green hydrogen commissioner James Mnyupe says the HyIron-Oshivelo project will reinforce the technology, known as Iron-to-Hydrogen (I2H), in Namibia.

The project is expected to begin DRI production by the end of the year.

“We are now engaging buyers for this DRI, who may use it in their steel making processes. We are also engaging auto manufacturers looking to decarbonise their scope three upstream related emissions.

These buyers are not just from Europe but include interested parties from Asia to South America and beyond,” Mnyupe said yesterday.

By tapping into existing iron ore reserves and harnessing extensive renewable resources, Mnyupe says Namibia is positioned as a crucial player in pioneering green hydrogen research and development, addressing escalating demands for clean energy across the globe.

“This means we are not producing hydrogen in Namibia for export, but we are rather using it to anchor and grow the secondary sector of our economy,” he said.

According to the study, DRI can store large amounts of energy which require very little additional energy to be released.

When combined with water, heat and a catalyst in a chemical process, the DRI reacts to form iron oxide (rust) and releases hydrogen. This can then be used to generate electricity in a power plant.

“The DRI has yet another potential use; a chemical reaction using steam may result in the DRI binding with the oxygen from the steam, releasing hydrogen in the process.

Therefore, we may be able to transport hydrogen across the seas by moving the DRI instead of trying to transport hydrogen itself.

This could have significant ramifications on how green hydrogen may be transported internationally,” Mnyupe added.

With its superior affordability, the I2H technology costs significantly less than other current methods, such as electrolysis in Germany, which costs €425/MWh (approximately N$8 059.77) or ammonia cracking at the cost of €581/MWh (approximately N$11 566.18), with imported DRI costing €402/MW (approximately N$7 623.60).

Stay informed with The Namibian – your source for credible journalism. Get in-depth reporting and opinions for

only N$85 a month. Invest in journalism, invest in democracy –

Subscribe Now!